PLEX ASSET PERFORMANCE MANAGEMENT

Maximize Machine Performance With A Comprehensive View Of The Plant Floor

What if you could identify potential failures before they happen?

With Plex Asset Performance Management (APM) by Rockwell Automation now you can.

Plex APM is a cloud-based solution that connects to machines on the plant floor and monitors machine health to drive predictive maintenance. Many leading manufacturers are turning to Plex APM to proactively monitor machine and plant health to ensure optimal uptime, throughput, and maintenance needs.

Explore Plex APM

Plex APM streamlines the process from data collection to actionable insights. Discover how Plex APM can enhance your understanding of efficiencies and predict potential failures before they occur.

Optimize Performance

Discover new opportunities to enhance production with contextualized process, machine-level, and operational data.

Improve Machine Health

Proactively prevent production equipment failure and unplanned downtime by keeping machines in optimal condition.

Streamline Maintenance Management

Take your maintenance practices from reactive to proactive with predictive analytics.

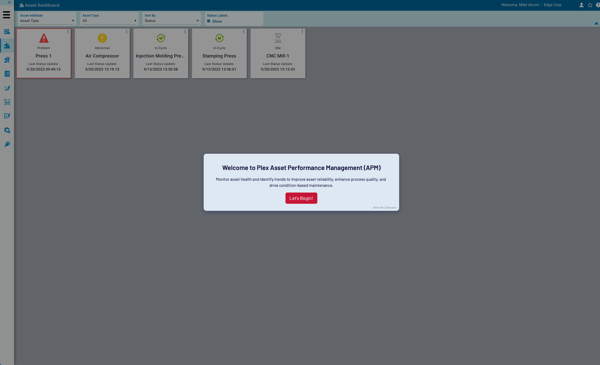

How it works: Transform insights into actions

Increasingly, manufacturers are recognizing the benefits of implementing solutions that enable machine connectivity and condition monitoring without the need for physical inspections.

Plex APM enhances the performance of production machinery, equipment, and assets, allowing for deeper data analysis and improved manufacturing outcomes with:

- Connectivity to virtually any asset or data stream

- Live dashboards for facilities, work cells, or assets with intuitive color coding

- Real-time asset status views (Off, In-Cycle, Idle, Problem, Other)

- Remote access to dashboards from any device, anytime, anywhere

- Historical views of asset status and event logs

- Data visualizations with graphical trend lines

- Integration of multiple data streams from machines and sensors

- Security controls to restrict access to authorized users

- Contextual insights combining process, operational, and machine data

You Have Symptoms. We Have Solutions.

When your machines malfunction, it creates a ripple effect that impacts all aspects of your manufacturing success. If you’re facing any of the challenges listed below, your operation will benefit from the Plex APM application:

Missed Deadlines: Equipment failures and unexpected downtime result in delays, missed deadlines, and decreased customer satisfaction.

Substandard Products: With Plex APM, manufacturers can set performance standards for their machines to ensure quality production. Plex APM swiftly notifies team members when machines operate outside these thresholds, enabling quick issue resolution.

Slow Recall Response: Despite the increasing frequency of product recalls, many manufacturers struggle to store and track the necessary data to respond effectively and safeguard their reputation.

Inefficient Micro-Stops: While major production interruptions are often easy to identify and resolve, micro-stops—brief yet frequent production halts—often go unnoticed, causing a significant impact on throughput and quality.

Expensive Equipment Repairs or Replacement: Without real-time performance data, manufacturers typically wait until machines break down or show severe malfunction signs before taking them offline for maintenance. This leads to costly repairs and increased shipping and production costs to fulfill customer commitments.

Plex APM in Action

Launch the interactive demo now to see exactly how Plex APM helps you to proactively monitor machine health.

Plex APM is a standalone component of the Plex Smart Manufacturing Platform- a cloud-based software-as-a-service solution that offers modules that can be implemented individually, as integrated components, or as a complete system.

Ready to learn more? Click below to request an in-depth demo

Questions? Click below to connect with our team of smart manufacturing experts